To provide users with a full range of bearings and services

Hong Kong New Century Bearing Co., Ltd. is a bearing company specializing in bearing sales and service. It has been serving the market for more than 20 years and has maintained a good bearing import business and supporting business with many foreign trading companies relying on Hong Kong port. The company has strong strength, abundant inventory, sufficient supply, and fast delivery. The products cover insulating bearings, stainless steel bearings, ceramic bearings, machine tool spindle bearings, automobile clutch bearings, automobile wheel bearings, truck bearings, agricultural machinery bearings, motor bearings, rolling mill bearings, textile machines. Bearings, printing press bearings, mining machinery bearings, excavator bearings, metallurgical bearings, high temperature bearings, miniature bearings, railway bearings, etc.

NEW CENTURY BEARING has built quality process control and product traceability system, which effectively guarantees the precise of products and stability of the performance.

The packaging process covers filling, wrapping, sealing, etc. The operation of packaging machinery helps introducing products to the circulation market successfully, and the technological innovation of the industry also greatly improves the production efficiency, not only effectively avoiding dust hazards

The market of medical equipment only using physical means (without pharmacology and immunology) to achieve efficacy is expanding all over the world. Due to the positioning of precision, it desires high rotating speed, high precision, low noise, low vibration and maintenance-free equipment.

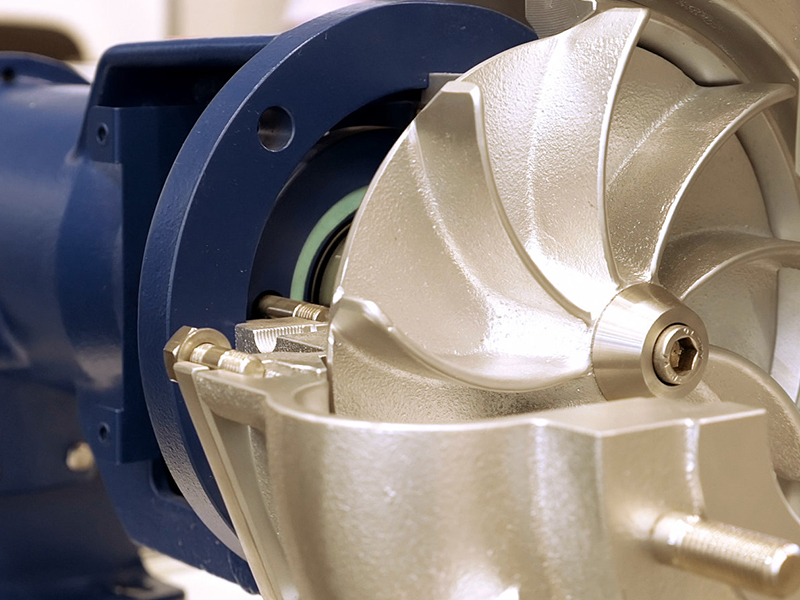

Pump, widely used in all fields, has been an indispensable part for industrial production. However, the operation and maintenance personnel in the pump industry in recent years are faced with many challenges such as high efficiency and energy saving, low

NEW CENTURY BEARING has built quality process control and product traceability system, which effectively guarantees the precise of products and stability of the performance.

We have perfect product solutions in various industries which can make you securely use our products.

Our company is committed to forge high quality products at competitive prices and contribute to industrial modernization.

New Century bearing has a sound delivery system,and rigorous criteria for packaging,transportation and delivery.

Follow us for the latest updates

Delivery of self-aligning roller bearings, customer satisfaction is our pursuit

Read More

Utilizing technologies exclusive to NSK, reconditionable large tapered bearings deliver three key features: long service life (high load capacity) for long-term use, a separable structure that allows for detailed examinations of bearing internals, and a staked-bolt design that prevents parts from loosening in environments with vibration. This combination of solutions built on NSK Core Technologies provides an industry-first in reconditionable large TRBs.

Read More

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Akitoshi Ichii) announced today that it has joined the 30by30 Alliance for Biodiversity, an initiative led by Japan’s Ministry of the Environment, as well as the global TNFD Forum, which supports the international efforts of the Taskforce on Nature-related Financial Disclosures (TNFD).

Read MoreLOOK FORWARD TO COOPERATING WITH YOU

Contact Us